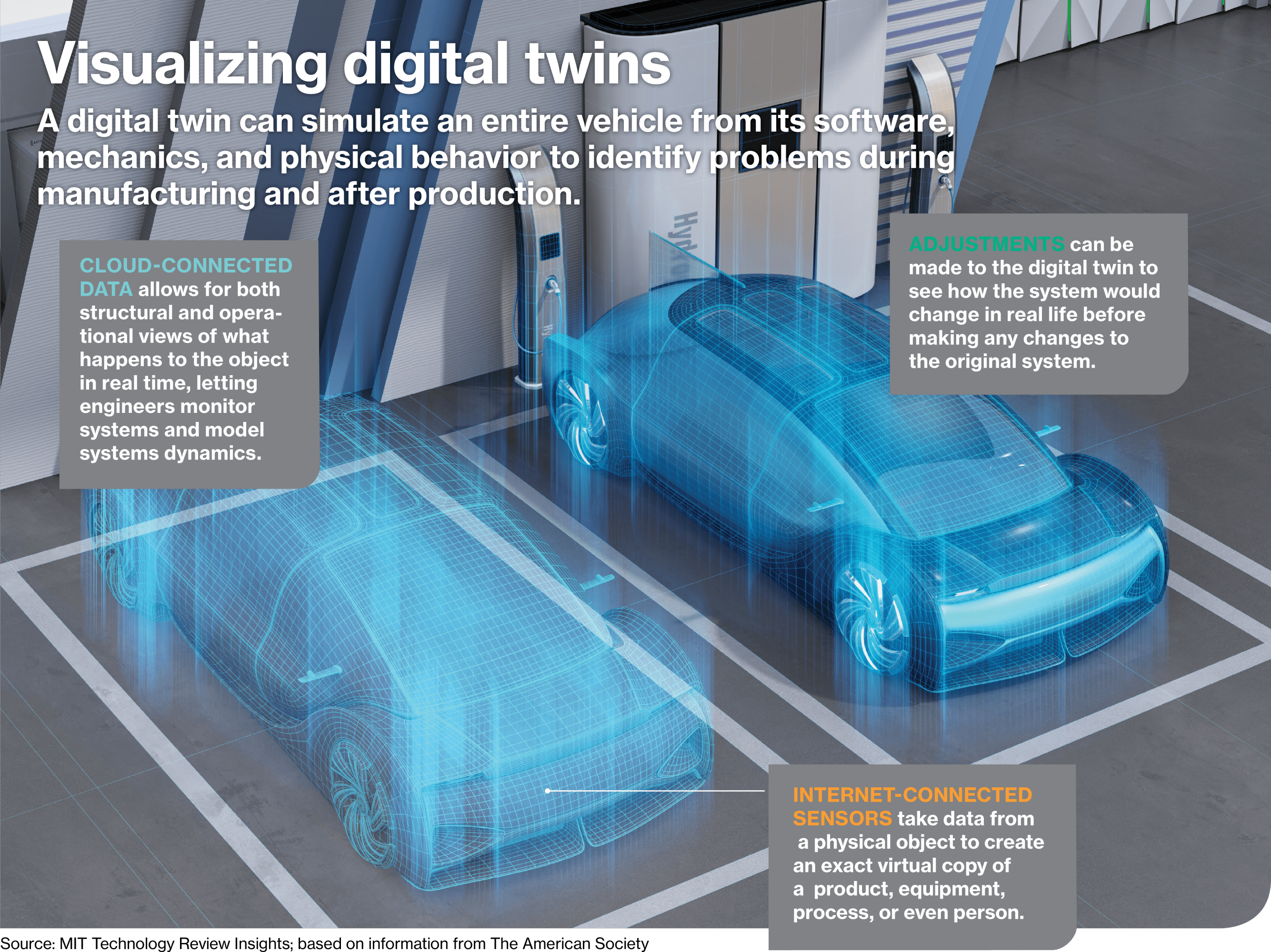

Real-world data paired with digital simulations of products – digital twins – provide valuable insights that help companies identify and solve problems before prototypes go into production and manage products on-site, says Alberto Ferrari, Senior Director of Model Based Digital Thread Process Capability Center at Raytheon.

“As they say, ‘All models are wrong, but some of them are useful,'” says Ferrari. “Digital twins, supported by data – as real facts – are one way of identifying models that are really useful for decision-making.”

The concept is picking up speed and the market for digital twin technologies and tools is growing 58% annually Reach $ 48 billion by 2026, up from $ 3.1 billion in 2020. Using the technology to create digital prototypes saves resources, money and time. But the technology also simulates far more, from urban populations to energy systems to the use of new services.

Take manufacturers as different as Raytheon and Swedish distillery Absolute vodkawho use the technology to develop new products and streamline their manufacturing processes, from supply chain to production to recycling and disposal. Singapore, London, and several cities on the Texas Gulf Coast created digital twins of their communities to address facets of city management, including modeling traffic patterns on urban roads, analyzing construction trends, and predicting the effects of climate change. And companies like Bridgestone and the drone service provider Zipline use the technology paired with operational data to launch new services.

Companies have adopted digital twins as part of their digital transformation to simulate performance, identify weaknesses, and operate services more efficiently. Any company’s digital initiative should investigate whether some aspect of its product, operation, or environment can be simulated for insights.

Simulation of construction and manufacturing

Today’s digital twin technologies are based on tools for computer-aided design (CAD) and computer engineering developed more than three decades ago. These software systems enabled engineers to create virtual simulations to test changes in product designs. Engineers designed a product component, such as an airfoil, on a computer and then hired a modeler or sculptor to make the item out of clay, wood, or bearing components for physical testing.

Today the process has moved the prototyping stage too much later in the process as the massive increase in computing power and memory makes it possible not only to prototype the entire product but also to incorporate other information such as: B. Information on raw material supply, materials, the components required for manufacture and the operation of the product in the field.

“If you looked at those CAD and engineering tools from 30 years ago and screwed up your eyes a little, you’d find they were digital twins,” said Scott Buchholz, chief technology officer for government and public services and director of research for emerging technologies at Deloitte Consulting. “As power computing and storage increased, the ability to run useful simulations increased, and we moved from low-fidelity renderings to high-fidelity simulations.”

The result is that digital twin technology has taken a wide variety of industries by storm. Manufacturers of expensive vehicles and infrastructure products benefit from the shortening of the design and development cycle, making aerospace companies, automobile manufacturers and urban planning authorities early adopters. But startups also rely on the simulate-first mentality to quickly repeat product improvements.

A big advantage: digital twins have displaced the physical construction of prototypes much further in the design pipeline. Some companies pursuing zero prototype initiatives are aiming to eliminate the prototyping steps entirely and enable direct-to-manufacturing efforts, said Nand Kochhar, vice president, automotive and transportation, Siemens Digital Industries Software .

That is a massive shift from earlier times. “A typical product development lifecycle was between six and eight years,” says Kochhar about automobile manufacturing. “The industry has worked on it, and now they have an 18 or 24 month life cycle. Now the automotive industry is more dependent on software, which is becoming the determining factor in the life cycle. “

Download the. down Complete report.