Nobody wants to be the maintenance worker who has to wander half a mile of damp hallways just to check the pressure gauge on a valve somewhere. LiLz makes it possible to remotely keep an eye on such inconvenient physical interfaces with a clever and practical application of machine learning.

The Japanese (especially Okinawan) startup has been around for some time – in fact our colleagues from TC JP wrote them down. But despite the seemingly obvious value of its service, it hasn’t quite made the breakthrough just yet. LiLz attended CES as part of the country’s trade group, along with a number of other companies listed here.

The device from LiLz looks a bit like a chubby tablet without a screen. It’s essentially a camera, light and processing and communication chips packaged with a large battery – enough power for up to three years.

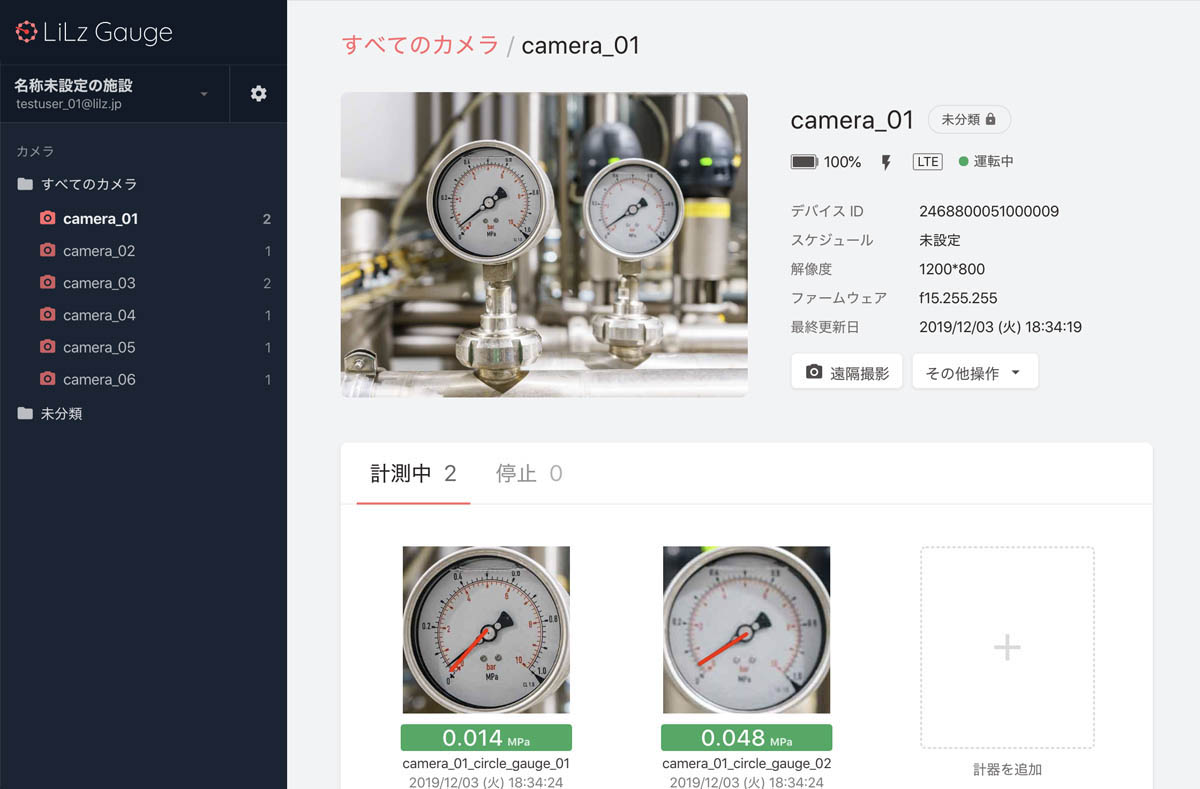

Mount the device so that it can see the meter or dial in question. After confirming the picture and signal, configure it in the app to interpret what it is pointed to; it can read circular, semicircular and linear displays, digital and scrolling or analog number displays, or things like colored warning lights. (The ML involved here is not trivial – I came across it this interesting article when looking.)

Once set up, it sends measured values live or at intervals to a central dashboard or makes them available via API so that they can be queried or recorded elsewhere. The data go out via LTE or Bluetooth.

Credit: LiLz

It is a solution aimed directly at infrastructure and heavy industry that often includes a lot of old equipment in hard-to-reach places: rooftops, underground (but not too deep or the signal cannot penetrate), in labyrinthine factories and warehouses, etc.

Turning these dials on a daily basis is not only boring for humans, it can also be dangerous. Using a robot is another way to automate this, but doesn’t a network of IoT devices seem more practical than a four-legged bot that is constantly driving around?

Kuba Kolodziejczyk, CTO of LiLz, said the company expanded rapidly after debuting in 2020 and a Series A round over $ 2.2 million in early 2021.

Credit: LiLz

“We grew from 240 cameras deployed by some early users in 34 locations before June 2020 to 2000 cameras now deployed in 320 locations to over 100 customers, and expect to grow to 5,000 cameras by the end of this year he wrote in an email to TechCrunch. “We now have some customers who have more than a hundred cameras in a single location.”

They started with basic facility management, but have expanded to include chemical and industrial plants, construction and manufacturing facilities, public infrastructure and more due to customer demand.

And the capabilities of the device are also increasing. They have mostly iterated on the software to remotely update it, improve accuracy and resilience to interference, and add data sharing and other features. There is also a new explosion-proof (!) Version of the hardware. Maybe they should make phone cases on the side.

New products are on the way, one for “sound finding” and one for counting objects in the camera’s field of view, but both are still in the very early stages. And new functions such as the monitoring of float and level indicators.

They have now come to CES to reach potential customers outside of Japan. The show looks like a bankruptcy, but maybe some technicians and managers will read this and think, “Wow, that would be handy.” Find out more at shiny new english website here.