Researchers at the Technical University of Munich in Germany have developed a technique to create heart valve scaffolds that can mimic the variable mechanical properties of the real thing. The researchers used a method called melt electrowriting to create complex and variable patterns in the fibrous scaffolds, allowing them to mimic the structure and mechanical properties of heart valves. The technique involves heating a polymer and then extruding the melted material through a print head to form very thin fibers on a moving surface. The researchers hope that the technique could lead to heart valve implants that encourage a patient’s own cells to populate and grow within.

Diseased heart valves are currently difficult to repair or replace, particularly in children, and researchers have been attempting to develop biomaterial alternatives for some time. However, part of the challenge lies in the variable mechanical properties of the valves, which have a heterogenous structure. Simply forming a valve shape using a homogenous biomaterial does not accurately mimic the variable stiffness and flexibility of real heart valves, and in a highly dynamic tissue like the heart this mismatch could significantly affect their functionality.

The researchers behind this latest study have attempted to mimic these variable biomechanical properties in their biomaterial scaffolds. “Our goal is to engineer bioinspired heart valves that support the formation of new functional tissue in patients,” said Petra Mela, one of the lead developers of the new technique. “Children would especially benefit from such a solution, as current heart valves do not grow with the patient and therefore have to be replaced over the years in multiple surgeries. Our heart valves, in contrast, mimic the complexity of native heart valves and are designed to let a patient’s own cells infiltrate the scaffold.”

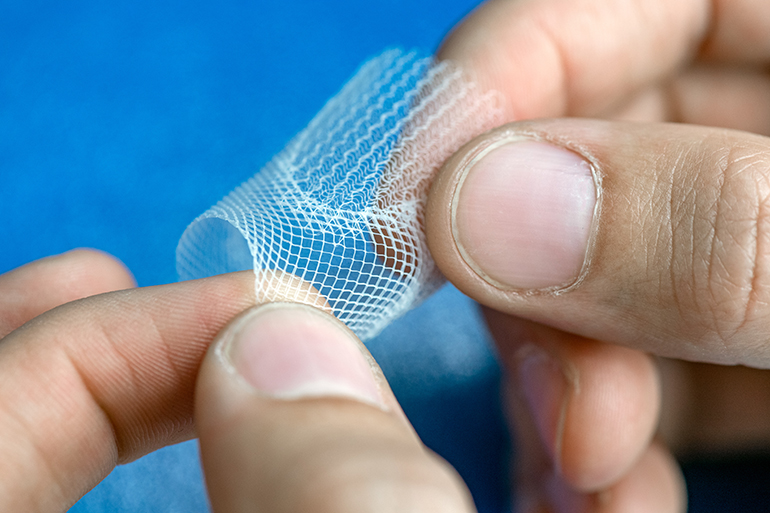

The melt electrowriting process involves applying high voltage while the melted polymer jet is extruded onto the surface below. This helps to stabilize the polymer jet, resulting in a more predictable printing process, and it also significantly narrows the diameter of the jet because it pulls it towards the surface below. The resulting fibers are therefore very narrow, with a diameter of five to fifty micrometers.

This fine control of the printed fibers lets the researchers create elaborate patterns, which helps them to modify the mechanical properties in different regions of the printed structure. A computer controls the movement of the structure during printing, and the user can design the patterns using the computer system before printing.

In an interesting twist, the researchers also experimented with impregnating the polymer with superparamagnetic iron oxide nanoparticles, which allows the resulting scaffolds to be observed and monitored using MRI after implantation.

Study in advanced functional materials: Spatially Heterogeneous Tubular Scaffolds for In Situ Heart Valve Tissue Engineering Using Melt Electrowriting