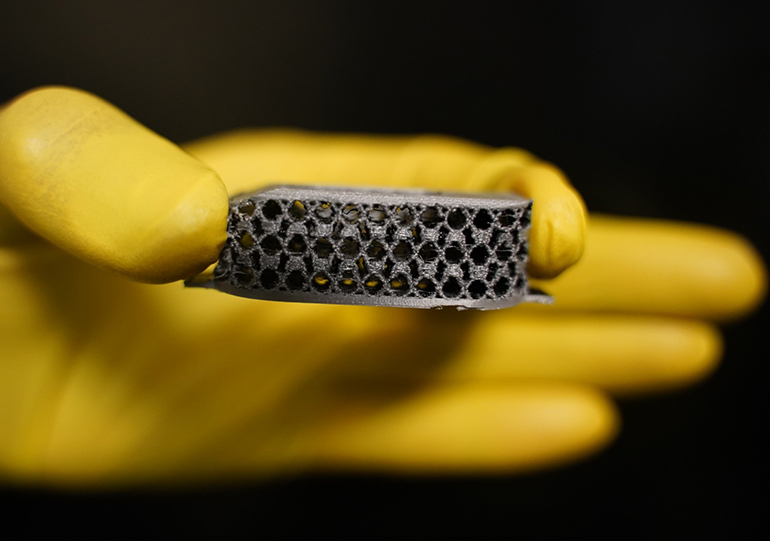

Engineers at the University of Pittsburgh created a self-powered implant that can track spinal healing while also providing mechanical support. The device can be 3D printed so that it fits a given patient perfectly and the mechanical properties can also be easily tuned to customize for each situation. The spinal fusion cage contains a triboelectric nanogenerator that creates electricity when it is pressurized by the spine. This powers an on-board sensor that measures the pressure on the cage, which is indicative of spinal healing.

Spinal fusion cages are often inserted by surgeons to provide support after fusion surgeries. However, these tend to be off-the-shelf solutions which are not particularly tailored for individual patients. This latest technological innovation aims to improve on that by not just making the design more customizable but also by introducing a self-powered sensor that provides information on spinal healing.

“Spinal fusion cages are being widely used in spinal fusion surgeries, but they’re usually made of titanium or PEEK polymer materials (a semi-crystalline, high-performance engineering thermoplastic) with certain mechanical properties,” said Amir Alavi, one of the developers of the new device. “The stiffness of our metamaterial interbody cages can be readily tuned. The implant can be 3D-printed based on the patient’s specific anatomy before surgery, making it a much more natural fit.”

The self-powered sensor uses a triboelectric nanogenerator that produces small amounts of electricity when it is subjected to pressure from the spine. Using an external ultrasound device, a clinician can read the data from the implant and get an idea of how the spine is healing.

“Smart implants can provide real-time biofeedback and offer many therapeutic and diagnostic benefits,” said Alavi. “But it is very challenging to integrate bulky circuits or power sources into the small area of implants. The solution is to use the implant matrix as an active sensing and energy harvesting medium. That’s what we’ve been focused on.”

So far, the researchers have tested the device in human cadavers, and hope to progress to animal studies soon. The data reporting technology also has potential in other implantable devices, such as stents and joint replacements.

“This is a first-of-its-kind implant that leverages advances in nanogenerators and metamaterial to build multifunctionality into the fabric of medical implants,” said Alavi. “This technological advancement is going to play a major part in the future of implantable devices.”

Study in advanced functional materials: Patient-Specific Self-Powered Metamaterial Implants for Detecting Bone Healing Progress