The company focused on solving the toughest problems early in the design phase with team sprints and then moved to smaller groups for detailed design efforts. They used quick feedback loops in simulation and testing to improve the design before going into production.

This focus on agile development and manufacturing helped Zipline take its unmanned aerial vehicle (UAV) from design to commercialized and scaled operation across Ghana and Rwanda in less than 18 months, and a final half year in design validation and engineering verification.

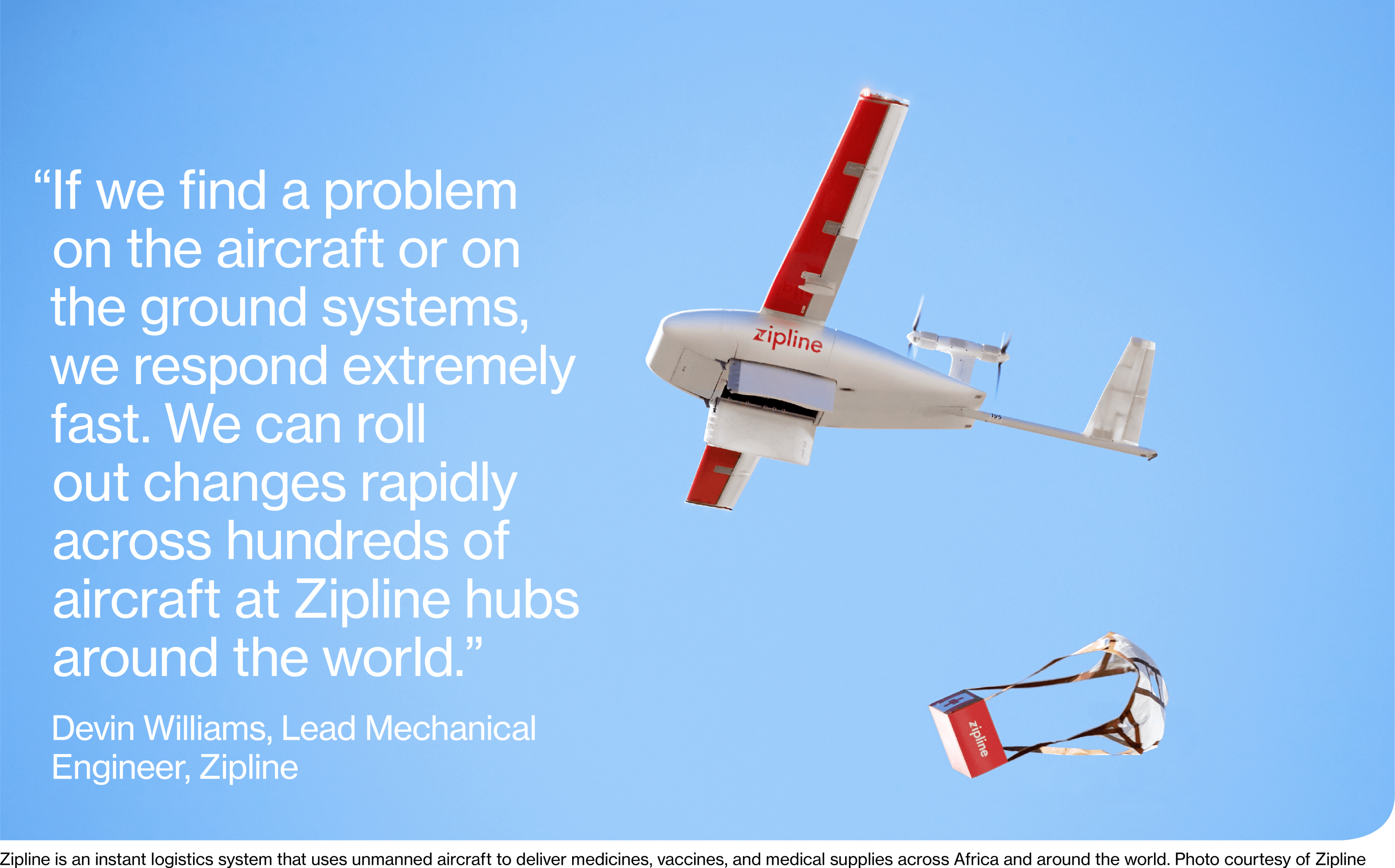

“In general, the idea of sprinting resources on a specific problem is something we’re taking from the software world back to the hardware world,” said Devin Williams, chief mechanical engineer for the UAV production platform at Zipline. “One thing we do really well is find the Minimum Viable Product and then prove it in the field.”

Using an agile process allows Zipline to focus on releasing changes to the product that meet customer needs quickly while maintaining high reliability. The San Francisco Bay Area company now has distribution centers in North Carolina and Arkansas, with another in Salt Lake City underway and soon to be rolled out in Japan and in new markets across Africa.

Zipline is not alone. From startups to manufacturers with decades of history, companies are turning to agile design, engineering, and manufacturing to create innovative products at a lower cost. Aircraft manufacturer Bye Aerospace has cut the cost of developing an electric aircraft by more than half and accelerated the pace of its prototypes. And Boeing won the TX-Twin-Pilot-Trainer-Jet project with the US Air Force with agile processes.

Overall, the use of agile methods should be a priority for every manufacturer. For aerospace and defense companies whose complex projects typically followed the long time horizons of waterfall development, agile design and development are required to lead the industry into the age of urban air mobility and the future of space exploration.

The evolution of traditional product design

While agile manufacturing has its origins in the Kanban method of just-in-time car manufacturing, which was developed at Toyota in the 1940s, the modern agile framework for development was refined in the late 1990s by programmers looking for better Were looking for ways to produce software. Rather than creating a “waterfall” development pipeline that includes specific phases like design and testing, agile development focused on creating a working product, the Minimum Viable Product, as early as possible in the process and then iterating over the technology. In 2000 has a group of 17 developers designed the agile manifesto, focuses on working software, individuals and interactions, and working with customers.

Over the past decade, agile software development has focused on DevOps – “Development and Operations” – creating the interdisciplinary teams and culture for application development. Likewise, design companies and product manufacturers have learned the lessons of agility and reintegrated them into the manufacturing lifecycle. As a result, manufacturing is now made up of small teams iterating on products, putting real lessons back down the supply chain, and using software tools to accelerate collaboration.

Agile offers advantages in the aerospace and defense industries, known for the complexity of their products and systems. When working on the development of the TX two-seat jet trainer, Boeing is committed to developing agile design and manufacturing processes, resulting in a half program cost increase for the U.S. Air Force, a 75 percent increase in the quality of the first prototype, half the software development time, and an 80 percent reduction in assembly time.

“We took an agile mindset and a block-plan approach to hardware and software integration,” says Paul Niewald, Boeing’s TX program manager. “That’s why we released software every eight weeks and tested it at the system level to validate our requirements. This enabled us to reduce our software effort by 50%. ”

In the end, TX went from design to building “production representation jets” in three years. This is a significant departure from the initial development of traditional aircraft programs, which use waterfall development in the initial design and development phase and can require a decade of development.

Download the. down Complete report.

This content was created by Insights, the custom content division of MIT Technology Review. It was not written by the editorial staff of MIT Technology Review.